Our client, a Pharmaceutical Contract Manufacturing company had a requirement to automate the paper based laboratory process to enhance competency. LIMS stands for laboratory information management system and represents a distinctive software package and database that stores and manages laboratory data, work flow and specialized processes like sample life cycle. In its basic form, it is applicable to R&D labs, QA labs and many more.

Business Challenge

- Pharmaceutical Quality Control Laboratories have an important function in raw material evaluation and in production and can significantly impact overall manufacturing performance.

- Lack of Built in in checks at potential error points increased manual errors. There is an increased cost associated with failure of lab process.

- Lack of a system that is able to manage data for a wide range of analytical techniques for both the raw materials and finished products.

- The Lab relied on semi-manual procedures and couldn’t easily generate useful analytical reports or produce electronic data deliverables (EDDs).

- Lab found it difficult to manage the workload efficiently.

Solution

- Custom made Laboratory Information management system catering to five primary criteria :

- Breadth of feature set

- Intuitive workflow and ease-of-use

- Integration capabilities

- Minimal ongoing maintenance and

- Affordability.

Key Results

Report Generation :

The solution provided a very quick way to generate reports for certain tasks such as Certificates of Analysis, monthly reports, trending, and validation paperwork. Very fast generation of validation documents compared with the old procedure was achieved.Productivity :

Productivity increased due to an intuitive workflow that closely mirrored the basic needs of the lab but automated many of the functions. Lab staff could move seamlessly from client information to project creation, work order entry, sample processing, detailed analysis, and reporting.Quality control :

Quality control also improved because of increased integration. eSoft LIMS came pre-loaded with 85-90 percent of the instruments used in the Lab and the balance were configured during the implementation process.Data Redundancy :

eSoft LIMS helped achieve less repetitive and error-prone data entry.Compliance :

Regulatory compliance became easier because the Lab gained the ability to produce EDDs, analytical reports and quality control.Technology

- CSS+HTML

- ASP.NET

- MYSQL

- MVC

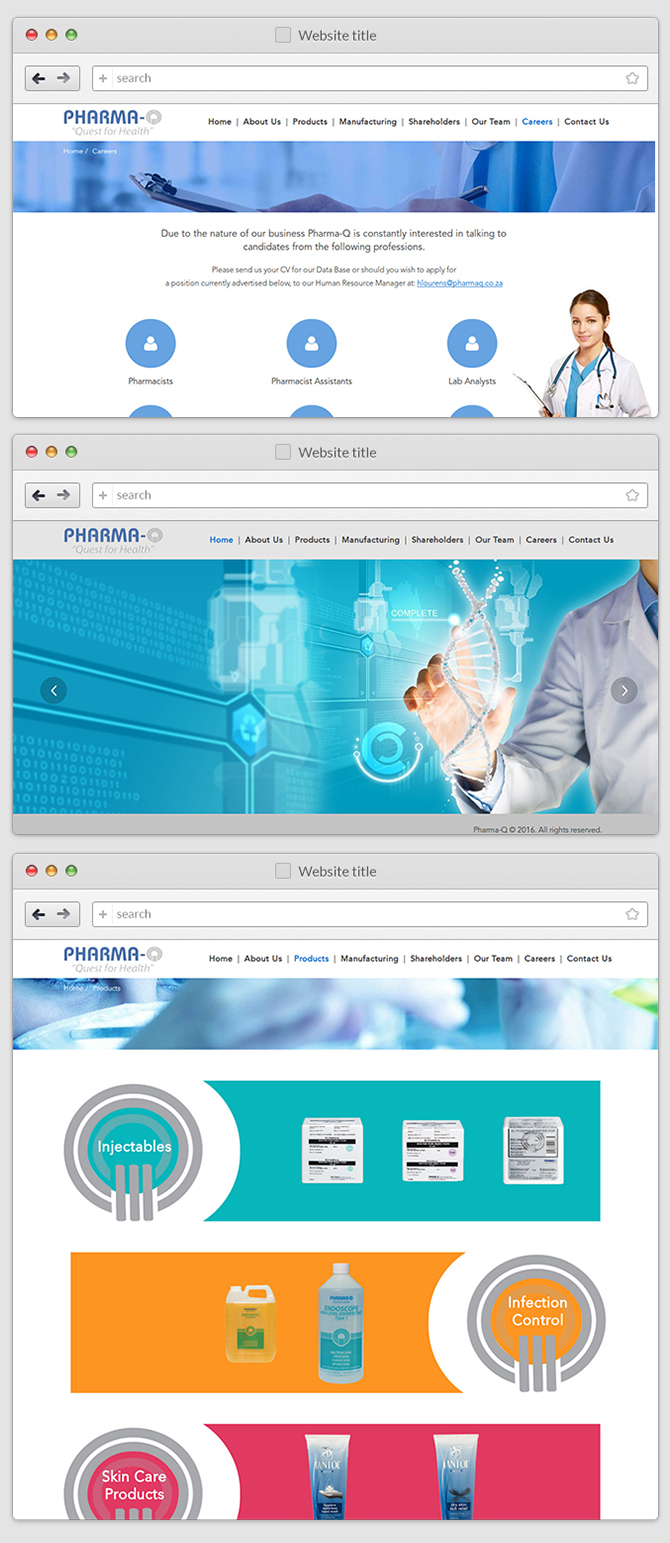

Client